CNC machining medical prototypes help you get very exact parts. These parts have tight tolerances for making medical devices. You can turn your design ideas into real models fast. This makes the process quicker and lets you test early. Rapid prototyping helps you change designs quickly and test them for safety. You can also check how well they work. Customization lets you make implants and prosthetics that fit each patient. This helps patients get better results. Scalable production gives you the same parts every time for tools and devices. This lowers mistakes and makes things work better. Key Takeaways CNC…

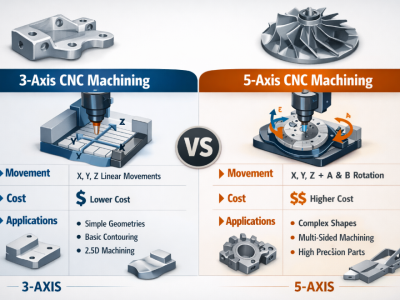

CNC machining allows you to create parts with very tricky shapes and small size limits, especially when it comes to cnc machining complex geometries. You must follow simple design rules to ensure your parts are easy to make, accurate, and cost-effective. New technology enhances CNC machining's ability to work with hard shapes. You can see significant advancements with multi-axis machines and CAM software: 5-axis machining enables you to produce turbine blades or medical implants in just one setup, effectively handling cnc machining complex geometries. These machines can reduce machining time by up to 84% compared to traditional methods. Hybrid manufacturing…

When you compare 3 axis vs 5 axis cnc machining for complex parts, you can see they operate differently in terms of shapes and speed. You might choose 3-axis cnc for simpler shapes. However, more challenging parts often require the additional movement capabilities of 5-axis cnc. Many companies now prefer 5-axis cnc because it can complete multiple sides in a single setup. This efficiency allows for faster workflows and time savings. If you are concerned about setup time and cost, 3-axis cnc may initially appear to be the more economical option. However, if your project demands numerous setups, it can…

When you want custom CNC parts, it's essential to consider quality, cost, and time. Many engineers face challenges with how to choose a CNC machining service, especially when it comes to early communication, collaborating on design, and selecting materials. Steel CNC machining can be particularly difficult because strong cutting and heat can lead to mistakes. Before you choose a CNC machining service, make sure you understand your project's needs and set clear goals. Early communication is crucial Material characteristics can affect results Establishing tolerance is very important Selecting the right partner helps prevent issues Key Takeaways Talk early and clearly…

You figure out cnc machining cost by looking at many things. These include material, machining time, complexity, and machine type. If you know about cnc costing, you can control your project’s budget. You can also avoid extra charges that you did not expect. Knowing each cost part helps you pick the best supplier. It also helps you plan production better. Cnc costs are different in each country: CountryAverage Hourly CostUSA$75–$200Canada$70–$180UK$60–$150Germany$70–$160China$30–$90 You should always use a detailed cnc costing report or tool. This helps you keep cnc costing correct. Key Takeaways Learn what things change CNC machining costs, like the material…

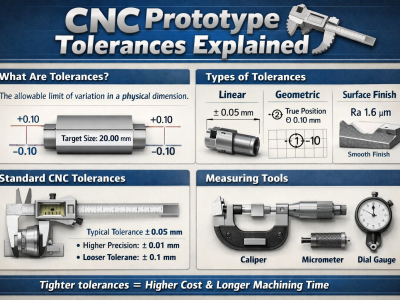

When you use CNC machining for prototypes, costs can change. The price depends on the material, how hard the part is to make, and how exact the measurements need to be. For example, if you use standard tolerances like ±0.1mm, the price stays low. But if you need very tight tolerances (less than ±0.01mm), the cost can be up to ten times higher. Look at the table to see how different things affect your choices: Cost DriverLow ImpactMedium ImpactHigh ImpactMaterialAluminum 6061, AcetalStainless Steel 304, Mild SteelTitanium, PEEK, InconelComplexitySimple block with holesMultiple faces, threadsThin walls, complex 3D contoursTolerancesStandard (±0.1mm)Tight (±0.025mm)Extremely Tight…

You should pick CNC text marking if you want deep and lasting marks on your parts. Laser marking is best for high accuracy, fast work, and clear marks. The CNC engraving process uses a computer system and a CNC engraving machine to cut into materials, while laser marking employs a laser engraver or laser marking machine that does not touch the part. Here is how CNC text marking vs laser marking differs: FeatureCNC Text MarkingLaser MarkingProcessTouches part, tool changesDoes not touch, quick setupDepthDeep (more than 0.5 mm)Shallow (0.1-0.3 mm)LegibilityHigh, depends on how deepHigh, always the sameCompatibilityWorks with many materialsNot for…

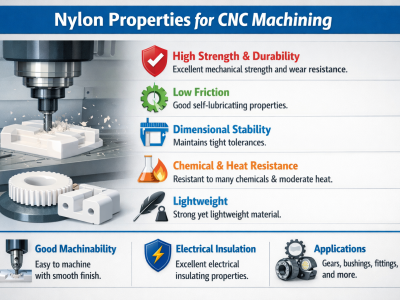

CNC Machined Nylon Parts: Strength, Precision, and Versatility CNC machined nylon parts have become a top choice for industries requiring durable, lightweight, and chemically resistant components. Nylon’s unique combination of mechanical strength, wear resistance, and low friction makes it ideal for applications where precision and longevity are critical. From automotive gears and bushings to electrical housings and industrial machinery components, machined nylon components deliver reliable performance under demanding conditions. One of the key advantages of nylon in CNC machining is its flexibility and toughness. Unlike metals, nylon can absorb impacts without cracking, while maintaining dimensional stability when exposed to moderate…

You use kovar machining services when you want very exact custom parts. Kovar is special because it is very strong, does not wear out easily, and can be welded well. These qualities make kovar good for tough places.Skilled workers and advanced methods help you get precise results with kovar machining. Many industries like electronics, aerospace, telecommunications, and medical devices use kovar for important parts. Key Takeaways Kovar machining makes custom parts that are strong and steady. These parts work well for electronics, aerospace, and medical uses. Advanced CNC machining uses special methods for tight tolerances. This means parts fit well…

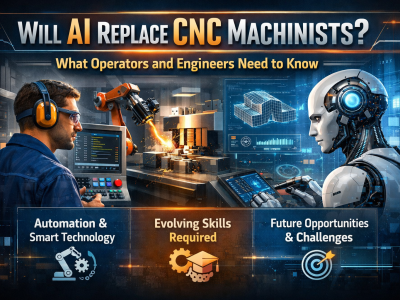

You might wonder, will AI replace CNC machining? The answer is no. Machinists remain crucial in the industry. While AI can enhance how you use CNC technology, it cannot fully replace what you do. Operators and programmers may notice some changes, as AI makes certain tasks easier, but your skills and adaptability are still essential. The future of CNC machining depends on humans and AI working together, not on the question of will AI replace CNC machining entirely. Key Takeaways AI will not take the place of CNC machinists. Your skills are still needed for hard jobs. Use AI tools…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.